Equipment and Reagent

Equipment:

1. Persee atomic absorption spectrophotometer A3F/AFG, equipped with nitrous oxide/acetylene gas supply, with Persee Al, Si hollow cathode lamps.

2. Burning furnace: capable of burning at 1000C with adequate air circulation

3. Platinum or silicon burning disks: capable of burning at 1000C

4. Stirring hotplate and magnetic bars, capable of heating at 200C

Reagent:

1. Aluminum Stock Solution 1000-ppm:

2. Silicon Stock Solution 200-ppm

3. Lithium Tetraborate (Li2B4O7)

4. HCl solution: add 50mL of HCl and constant volume to 1000mL with pure water

5. Blank solution: prepare a solution of 2g/L Li2B4O7 in HCl solution

Standard solutions:

1. Al Standard Solution (Al content 5, 10, 15, 20, 30mg/L): transfer 0.50, 1.0, 1.5, 2.0, 3.0mL of Al Stock Solution 1000-ppm into 100mL volumetric flask, dilute to 100mL with Blank Solution and mix well.

2. Si Standard Solution (Si content 10, 15, 20, 25, 30mg/L): transfer 5, 7.5, 10, 12.5, 15mL of Silicon Stock Solution 200-ppm into 100mL volumetric flask, dilute to 100mL with Blank Solution.

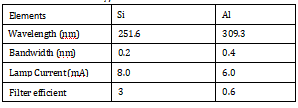

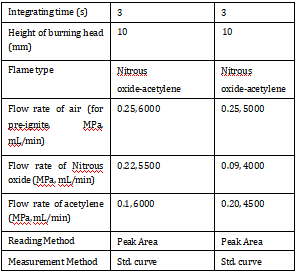

Equipment Condition

Instrument Working Parameters:

Table 1. Instrument Working Parameters.

Coal Sample Preparation:

Pulverize sample, take homogeneous parts and pass 250 μm sieve

↓

Determine moisture content (heat at 107±2 C until mass constant, divided by original mass) if required

↓

[Combustion]Put sieved sample (a thin layer) onto a roasting dish and put it in burning furnace. Heat to 500C

for 1 hr, then rise temp to 750C for 3 hr. Set until room temperature.

↓

Grind sample until all of sample pass through 75 μm sieve

↓

Heat at 500C for another 1hr

↓

Take 0. 1g sample to a silicon or platinum dish, add 0.5g Li2B4O7 and mix well.

↓

Add another 0.5g Li2B4O7 cover the mixture.

↓

[Fusion and dissolve] heat mixture 1000C for 1hr

↓

Set until room temp. Rinse the outside of the dish carefully. Then, take it to a beaker and add around

150mL HCl solution with a stirring bar. Heat and stir just below boiling for 30min. Make sure there’s no visible precipitate in the beaker.

↓

Set until room temp. Then, take the liquid to a 200mL volumetric flask. Rinse the bar, dish and beaker with HCl solution and transfer the washing liquid into the flask as well. Constant the volume with HCl solution to 200mL.

↓

Take 20mL of the above solution and constant volume to 50mL as testing solution.

Experiment Procedure

Note: change the concentration of standards and dilute the testing accordingly if it’s not appropriate.

Standard Curve: Al

Apply the Al lamp. Preheat for 30min. Adjust the energy well. Apply instrument parameters as in the figure above.

Test the Abs for: Blank solution, Al Standard Solutions (Al concentration of 5, 10, 15, 20, 30mg/L) and testing solution. Use Persee AAS software AAWIN to make standard curve and calculate automatically.

Standard Curve: Si

Apply the Si lamp. Preheat for 30min. Adjust the energy well. Apply instrument parameters as in the figure above.

Test the Abs for: Blank solution, Si Standard Solutions (Si concentration of 10, 15, 20, 25, 30mg/L) and testing solution. Use Persee AAS software AAWIN to make standard curve and calculate automatically.

Results

To ensure a reliable result, try to achieve a linear ratio of over 0.995. The sensitivity of the experiment is high.

The detection limits of Al and Si are 1.5mg/L and 0.002mg/L. The RSD value of the mixed standard solution is 0.78%.