Descubrir lo que’ La gasolina es muy importante. Ayuda a asegurarse de que el producto es bueno, sigue las reglas y funciona bien. Un método fuerte llamado cromatografía de gases (GC) se utiliza mucho en el negocio del petróleo para esto. Crea un gráfico específico, el cromatograma de gasolina. Este gráfico muestra una imagen de todos los diferentes hidrocarburos y otras cosas en el combustible. Así que’ es la clave para saber cómo calcular y leer este cromatograma para obtener evaluaciones correctas de calidad y cantidad.

Descripción general de la cromatografía de gas en el análisis de gasolina

La cromatografía de gas tiene un papel enorme en la actualidad’ s laboratorios de pruebas petroquímicas. Es’ Es ideal para separar, identificar y medir mezclas complejas como la gasolina. Y la gasolina tiene cientos de hidrocarburos diferentes.

El papel del GC en las pruebas de productos petroleros

El GC es realmente necesario para probar productos petroleros. Esto es porque’ Es muy preciso, sensible y puede funcionar bien con compuestos orgánicos que se evaporan fácilmente. También ayuda a los laboratorios a seguir las normas ambientales. Por ejemplo, lo hace midiendo cosas malas como el benceno y otros aromáticos.

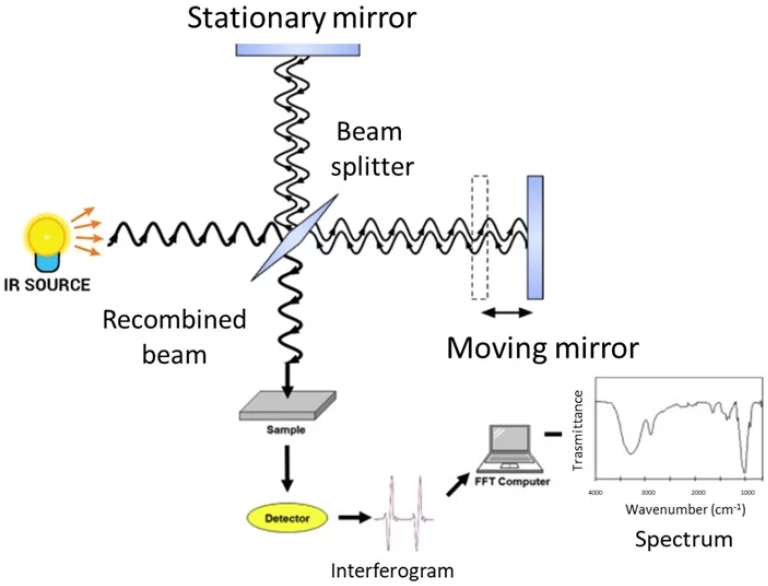

Componentes clave y funcionalidad de un sistema GC

Un sistema GC normal tiene algunas partes. Estos incluyen un inyector, una columna mantenida dentro de un horno, un suministro de gas portador, detectores y software para recopilar datos. En primer lugar, la muestra se convierte en un gas en el inyector. Luego, un gas que no’ t reacciona (generalmente helio) lo mueve a través de la columna. Aquí, sus partes se separan dependiendo de cómo interactúan con el material dentro de la columna.

Importancia del análisis cromatográfico para la composición de la gasolina

Este tipo de análisis da una imagen única de la gasolina’ maquillaje químico. ¿Qué’ Además, permite a las refinerías comprobar los niveles de octano y encontrar impurezas. Esto garantiza que el combustible cumpla con los límites legales para el contenido aromático. Las refinerías a menudo cambian la cantidad de aromáticos en el gas. Hacen esto para aumentar la calificación de octano y hacer que funcione mejor en general.

Métodos ASTM para el cálculo del cromatograma de gasolina

Varias normas ASTM muestran a los laboratorios cómo calcular cromatogramas de gasolina correctamente.

Introducción a las Normas ASTM relevantes (por ejemplo, D5134, D4815, D5580)

Algunos métodos comunes son ASTM D5134 (para una visión detallada de los hidrocarburos), ASTM D4815 (para oxigenados), ASTM D5580 (para aromáticos con un GC especial) y ASTM D5769 para aromáticos que usan GC-MS.

Propósito y alcance de cada método

Cada método se centra en ciertos grupos de compuestos:

- ASTM D5134: proporciona un análisis detallado de los tipos de hidrocarburos.

- ASTM D4815: Medir compuestos oxigenados, como el etanol.

- ASTM D5580: Medir benceno y todos los aromáticos utilizando GC multidimensional.

- ASTM D5769: Una forma estándar de encontrar aromáticos en gasolina con cromatografía de gases-espectrometría de masas (GC-MS).

Criterios de selección para el método ASTM apropiado basado en la aplicación

El método que elijas depende de lo que quieras saber. Siguir la ley puede significar que necesita usar D5769 para los límites de benceno. Por otro lado, para ajustar el rendimiento, puede usar el D5134 para obtener un perfil completo de hidrocarburos.

Técnicas de preparación y inyección de muestras

Obtener los resultados correctos comienza con manejar la muestra de la manera correcta.

Procedimientos de muestreo adecuados para un análisis preciso

Usted debe recoger muestras en recipientes sellados para que el combustible no’ t evaporarse. Además, mezclar bien la muestra justo antes de inyectarla asegura que sea consistente.

Técnicas comunes de inyección usadas en el análisis de gasolina

El método de inyección cambia la claridad y sensibilidad de los resultados.

Métodos de inyección divididos vs. sin división

La inyección dividida es excelente para muestras fuertes como la gasolina; Reduce el riesgo de sobrecarga del sistema. La inyección sin divisiones funciona bien para encontrar pequeñas cantidades de cosas, pero tienes que cronometrarla justo.

Columna empaquetada vs. inyección de columna capilar

Las columnas capilares te dan resultados mucho más claros porque son tan estrechas. Las columnas empaquetadas no son tan comunes ahora. Sin embargo, pueden ser útiles para ciertos trabajos que necesitan tamaños de muestra más grandes.

Condiciones cromatográficas y ajustes del instrumento

Los ajustes del instrumento deben configurarse correctamente para obtener una buena separación de los compuestos.

Programación de temperatura y control del horno

Aumentar lentamente la temperatura ayuda a empujar los compuestos fuera de la columna en función de la facilidad con que se convierten en gas. Un programa normal comienza a una temperatura baja (como 35 ° C), sube rápidamente (tal vez 25 ° C / min), y luego se mantiene a una temperatura alta para asegurarse de que todo salga.

Selección de gas portador y optimización del caudal

A la gente le gusta usar Helio porque’ es eficiente y no’ t reaccionar. Mantener el caudal igual asegura que obtenga los mismos resultados cada vez.

Tipos de detectores adecuados para el análisis de hidrocarburos

Dos detectores son los principales utilizados para encontrar hidrocarburos:

Detector de ionización de llama (FID)

Un FID es muy sensible a los compuestos orgánicos y tiene muy poco ruido. Esto lo hace perfecto para el análisis diario de gasolina.

Detector de conductividad térmica (TCD)

El TCD no es tan sensible. Sin embargo, es’ es útil porque puede detectar gases inorgánicos o cuando solo necesitas detectarlo todo.

Parámetros de adquisición e integración de datos

El procesamiento de los datos de la manera correcta asegura que sus mediciones son correctas.

Técnicas de detección de picos y corrección de referencia

Los algoritmos de software encuentran los picos que se destacan del ruido de fondo. Además, las funciones de suavización pueden hacer que los picos se vean más claros sin arruinar los resultados.

Calibración del tiempo de retención utilizando mezclas estándar

Debe inyectar regularmente estándares con productos químicos conocidos. Esto es para calibrar los tiempos de retención. Hacer esto asegura que pueda identificar los compuestos correctamente en cada carrera.

Ajustes de integración para garantizar la coherencia

Cosas como la altura del umbral, el ancho del pico y la sensibilidad de la pendiente deben mantenerse iguales para todos los análisis. Así, obtendrás resultados reproducibles.

Análisis cuantitativo de los componentes de la gasolina

La cuantificación es cómo se convierten las áreas de pico en números de concentración reales.

Método de Normalización de Área vs. Método Estándar Externo

La normalización de área funciona asumiendo que el área total de todos los picos es del 100%. El método estándar externo es diferente; utiliza curvas de calibración hechas a partir de concentraciones conocidas. Es’ es más preciso, especialmente cuando se utilizan estándares internos.

Cuándo utilizar cada enfoque de cuantificación

Puede usar la normalización cuando no’ Tener cualquier estándar. Sin embargo, debe utilizar el método estándar externo cuando necesita ser muy exacto o para la presentación de informes legales. Un buen ejemplo es encontrar el contenido de benceno según ASTM D5769.

Cálculo de concentraciones de componentes a partir de áreas de pico

Para obtener una idea de la concentración de cada componente, simplemente multiplica el área de pico por un factor de respuesta.

Conversión de área de pico a porcentajes de volumen o peso

Puede calcular los porcentajes de peso correctamente utilizando el método de normalización de área corregida. Primero, multiplica cada componente’ s área de pico por su propio factor de respuesta para obtener un “ zona corregida. ” A continuación, agrega todas las áreas corregidas. El porcentaje final en peso para cada componente se encuentra con esta fórmula: % en peso = (Área corregida individual / Área corregida total) × 100.

Interpretar los resultados del cromatograma con precisión

Leer un cromatograma de gasolina es más que solo encontrar picos. Tienes que saber lo que significa en el contexto.

Identificación de hidrocarburos por correspondencia de tiempo de retención

Los compuestos se determinan combinando sus tiempos de retención con los de mezclas estándar que se ejecutaron bajo las mismas condiciones exactas.

Tratar la co-elución y los picos superpuestos

A veces los picos se superponen. La espectrometría de masas realmente ayuda a solucionar este problema mirando los espectros de masas en lugar de solo el tiempo de retención. Esto es especialmente útil en cosas complejas como la gasolina.

Fuentes comunes de errores en la interpretación

Los errores pueden suceder. Pueden provenir de una mala calibración, una línea de base a la deriva, la configuración de integración incorrecta o el envejecimiento de la columna, lo que puede afectar los tiempos de retención o las formas de pico.

Procedimientos de control de calidad y validación

Para asegurarse de que su análisis es fiable, debe realizar algunas verificaciones de validación rigurosas antes de informar los resultados.

Pruebas de idoneidad del sistema antes de ejecutar la muestra

Las comprobaciones de idoneidad del sistema incluyen cosas como la resolución entre picos clave (>2.0), tiempos de retención estables y relaciones señal-ruido. Para una buena cuantificación, la relación señal-ruido para su estándar de calibración más bajo debe ser mejor que 10 (S/N > 10).

Validación de curvas de calibración y comprobaciones de linealidad

Tienes que mostrar linealidad a través del rango de concentraciones que espera ver. Un buen valor de r2 de más de 0,99 es típicamente necesario por el método.

Análisis de réplicas y verificación estadística

La inyección de la misma muestra más de una vez verifica la precisión (% RSD). La exactitud se verifica utilizando materiales de referencia certificados. Los resultados finales deben estar cerca de los valores certificados.

PERSEE: un socio confiable para el análisis petroquímico

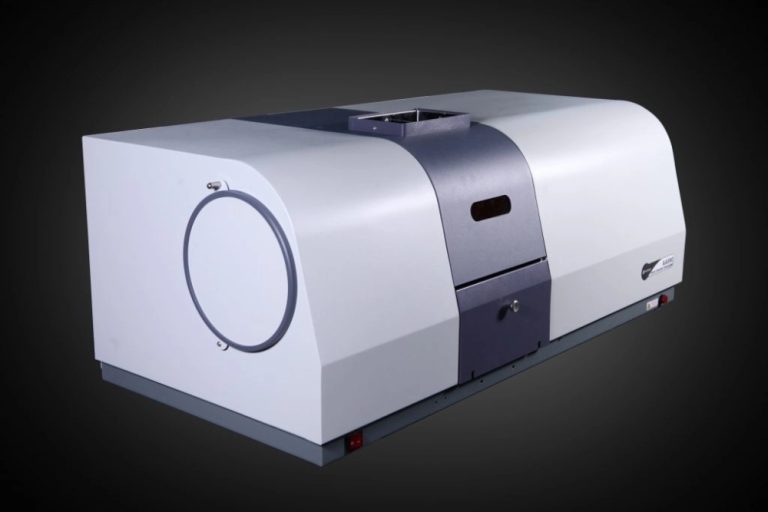

Perseguir tiene una línea de soluciones de cromatografía de gas fuertes y estables para laboratorios petroquímicos. Sus series G5 y GC1100 son excelentes para analizar muestras complejas como la gasolina.

Características clave del Sistema GC G5

- Rendimiento superior del horno de columna: El G5 tiene un amplio rango de temperatura de funcionamiento (ambiente de 4°C a 450°C). También se calienta y enfría muy rápidamente (hasta 120°C/min). Esto es muy importante para mejorar los métodos y reducir los tiempos de análisis. Su sorprendente precisión de control de temperatura (± 0,01 ° C) asegura que los tiempos de retención son estables y los resultados son reproducibles.

- Opciones flexibles de inyector y detector: El sistema puede utilizar diferentes entradas (como capilares empaquetados, divididos / sin división) y detectores (FID, TCD, ECD). Esto permite a los usuarios configurarlo para los requisitos específicos del método ASTM (como D5580, D4815). Así que’ Es bueno para muchos usos, desde el análisis normal de hidrocarburos hasta la búsqueda de pequeñas cantidades de contaminantes.

- Control Electrónico Avanzado (AEC): El G5’ AEC de alta tecnología le da control digital sobre los gases portadores y detectores. Tiene una precisión de ajuste de presión de hasta 0,001 psi. Esto asegura que el análisis sea estable y repetible, y también facilita su uso.

El GC1100Una opción clásica y práctica

- Diseño estable y robusto: El GC1100 es un sistema GC clásico. Es’ Es conocido por ser resistente y fiable. También tiene varias opciones de detector. Su detector de ionización de llama (FID) es especialmente sensible y puede detectar cantidades tan pequeñas como ≤3×10 ⁻ ¹² g/s. Esto lo hace perfecto para medir la cantidad exacta de componentes de hidrocarburos en la gasolina.

- Interfaz fácil de usar: El sistema’ El teclado y la pantalla de fácil uso permiten a la gente configurar métodos rápidamente y comprobar el instrumento’ estado. Esto lo convierte en una gran opción para laboratorios de control de calidad ocupados.

Así que, ya sea que necesite el rendimiento de alta tecnología y la flexibilidad del G5 o el confiable y rentable GC1100, PERSEE’ Los sistemas GC le dan tecnología en la que puede contar para ser precisos y seguir las reglas para su análisis cromatograma de gasolina.

Preguntas frecuentes

Q1: ¿Qué muestra un cromatograma de gasolina?

R: Un cromatograma de gasolina muestra las diferentes partes de hidrocarburos separadas con el tiempo a medida que se mueven a través de una columna de cromatografía de gas. Cada pico es uno o más compuestos que se pueden identificar por su tiempo de retención o espectro de masas.

Q2: ¿Por qué el contenido de benceno se controla de cerca en el combustible?

R: El benceno es una causa conocida del cáncer. Por lo tanto, hay reglas al respecto en combustible en todo el mundo, a menudo 1,0% o menos. Medirlo correctamente con métodos como ASTM D5769 ayuda a mantener a las personas seguras y también se asegura de que las empresas están siguiendo las regulaciones.

Q3: ¿Puedo usar un método GC para todos los tipos de muestras de combustible?

R: No siempre. Los diferentes combustibles tienen diferentes aditivos o hidrocarburos en ellos, por lo que a menudo necesitan métodos especiales. Por ejemplo, puede necesitar ASTM D4815 para oxigenados o D5134 para un perfil completo de hidrocarburos. Todo depende de lo que estés tratando de descubrir o de qué reglas debes seguir.