- Метод принцип

После соответствующей предварительной обработки образец вводится в атомизатор с графитовой трубкой. Ионы свинца диссоциируют на атомарный пар при высоких температурах внутри графитовой трубки. Атомы в основном состоянии целевого элемента поглощают резонансную линию, излучаемую лампой со свинцовым полым катодом, и интенсивность поглощения пропорциональна концентрации свинца в определенном диапазоне, что позволяет проводить количественный анализ содержания свинца.

- Инструменты и реагенты

- Инструменты и оборудование

- Приборы для обнаружения:

- Электрическая плита с регулируемой температурой (комнатная температура-300°C)

- Колориметрические пробирки объемом 10 мл

- Микропипетки (20 мкл-200 мкл, 100 мкл-1000 мкл, 1000 мкл-5000 мкл)

- Волюметрические колбы объемом 100 и 1000 мл

- Оборудование для предварительной обработки: То же, что и приборы для обнаружения, используется для переваривания проб и подготовки растворов.

- Реагенты

- Ключевые реагенты:

- Азотная кислота MOS-класса.

- Раствор азотной кислоты 1+99: Добавьте 10 мл азотной кислоты в колбу объемом 1000 мл, содержащую небольшое количество воды, и разбавьте водой до метки.

- Стандартные решения:

- Раствор: Стандартный исходный раствор свинца GBW(E)082818-2, 1000 мкг/мл.

- Промежуточный раствор: 100 мкг/мл (готовится путем разбавления 10,0 мл исходного раствора до 100 мл 1+99 азотной кислотой; стабилен в течение 1 недели).

- Рабочий раствор: 1,0 мкг/мл (готовится путем разбавления 1,0 мл промежуточного раствора до 100 мл азотной кислотой 1+99; свежеприготовленный перед использованием).

- Стандартная серия: 0,00, 2,50, 5,00, 10,00, 20,00, 30,00, 40,00 мкг/л (готовятся путем разбавления рабочего раствора).

Iii.

- Приготовление образца

- Предварительная обработка:

- Образцы чистой воды могут быть измерены напрямую.

- Образцы с высоким содержанием взвешенных частиц требуют подкисления и сбраживания органических веществ (конкретные этапы сбраживания не описаны).

- Приготовление стандартного раствора: Поэтапно разбавьте исходный раствор, чтобы приготовить промежуточный, рабочий и стандартный растворы, доведенные до объема 1+99 азотной кислотой.

- Образец тестирования

- Условия тестирования:

- Спектральные параметры:

- Длина волны: 283,3 нм

- Спектральная полоса пропускания: 0,4 нм

- Ток лампы элемента: 3,0 мА

- Коррекция фона: Дейтериевая лампа

- Объем инъекции: 15 мкл

- Программа отопления графитовой печи:

- Сушка: 110°C, темп 10 с, выдержка 10 с, высокий поток внутреннего газа.

- Озоление: 350°C, темп 10 с, выдержка 10 с, высокий поток внутреннего газа.

- Распыление: 1700°C, темп нарастания 0 с, выдержка 3 с, отключение внутреннего потока газа.

- Очистка: 1900°C, темп нарастания 1 с, выдержка 2 с, высокий расход внутреннего газа.

- Этапы измерения: Внесите холостой реагент, стандартную серию и образцы в графитовую трубку для измерения абсорбции. Вычтите абсорбцию холостого раствора из абсорбции каждого стандартного раствора, постройте рабочую кривую с зависимостью абсорбции (ордината) от концентрации свинца (абсцисса) и определите концентрацию свинца в образце по кривой.

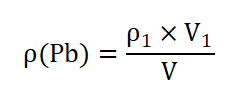

- Расчет результатов

Где:

-ρ(Pb): Концентрация свинца в образце воды (мкг/л);

-ρ1: концентрация свинца в образце, полученная по калибровочной кривой (мкг/л);

-V1 : объем исследуемого образца (мл);

- V: объем исходного образца воды (мл).

- Методологические параметры

- Минимальная обнаруживаемая массовая концентрация

- Предел обнаружения: рассчитан на основе 11 холостых измерений. Стандартное отклонение S0 = 0,00044, уравнение калибровочной кривой A = 0,0060C + 0,0013, коэффициент корреляции 0,99915. Предел обнаружения: 0,22 мкг/л; минимальная обнаруживаемая массовая концентрация: 0,88 мкг/л.

- Точность

- Результаты проверки: В результате семи повторных измерений одного и того же образца среднее значение абсорбции составило 0,1509, стандартное отклонение - 0,0046, а относительное стандартное отклонение (RSD) - 3,0%, что соответствует требованиям к точности.

- Точность

- Испытание стандартных образцов:

- Образец 201237 (стандартное значение: 42,0 нг/мл): Среднее измеренное значение 42,425 нг/мл, в пределах расширенной неопределенности (3,1 нг/мл).

- Образец 201236 (стандартное значение: 152,0 нг/мл): Среднее измеренное значение 147,85 нг/мл, в пределах расширенной неопределенности (12 нг/мл).

- Фактическое измерение образца

- Параллельные измерения трех проб поверхностной воды показали относительные погрешности 3,62%-4,31%, что соответствует требованиям параллельности.

- Меры предосторожности

- Предварительно обработайте образцы воды с высоким содержанием взвешенных частиц, чтобы устранить органические помехи.

- Приготовьте стандартные растворы путем пошагового разведения для обеспечения точности концентрации.

- Строго контролируйте программу нагрева графитовой печи, чтобы избежать фоновых помех и неполного распыления.