La microespectrofotometría es un método analítico muy eficaz. Combina la precisión de la espectrofotometría con la capacidad de estudiar muestras pequeñas. Esto permite a los científicos observar áreas extremadamente pequeñas, como fibras individuales o células. Además, esta técnica es un gran problema en campos como la ciencia forense, las pruebas de materiales y la comprobación de la calidad de los textiles. En el núcleo de todo esto está la espectrofotometría UV-Vis. Este es un método que mide la cantidad de luz que un material absorbe o deja pasar a través de diferentes longitudes de onda.

Fundamentos de la espectrofotometría UV-Vis

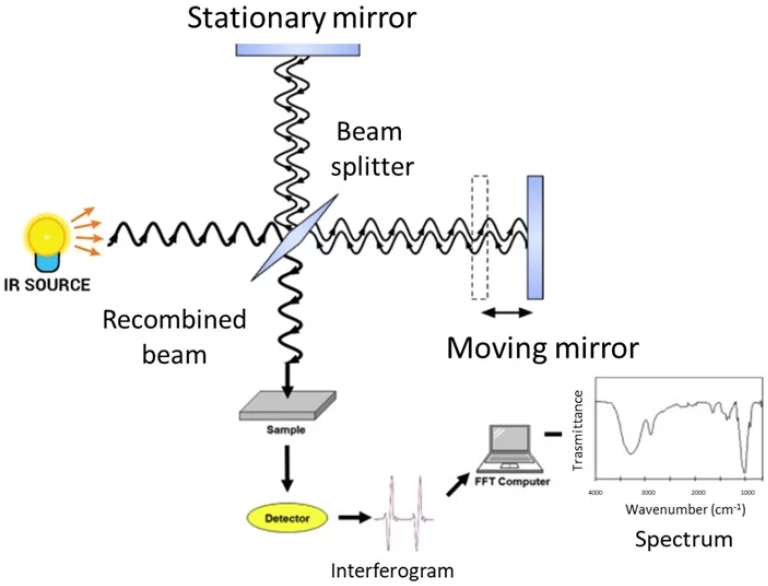

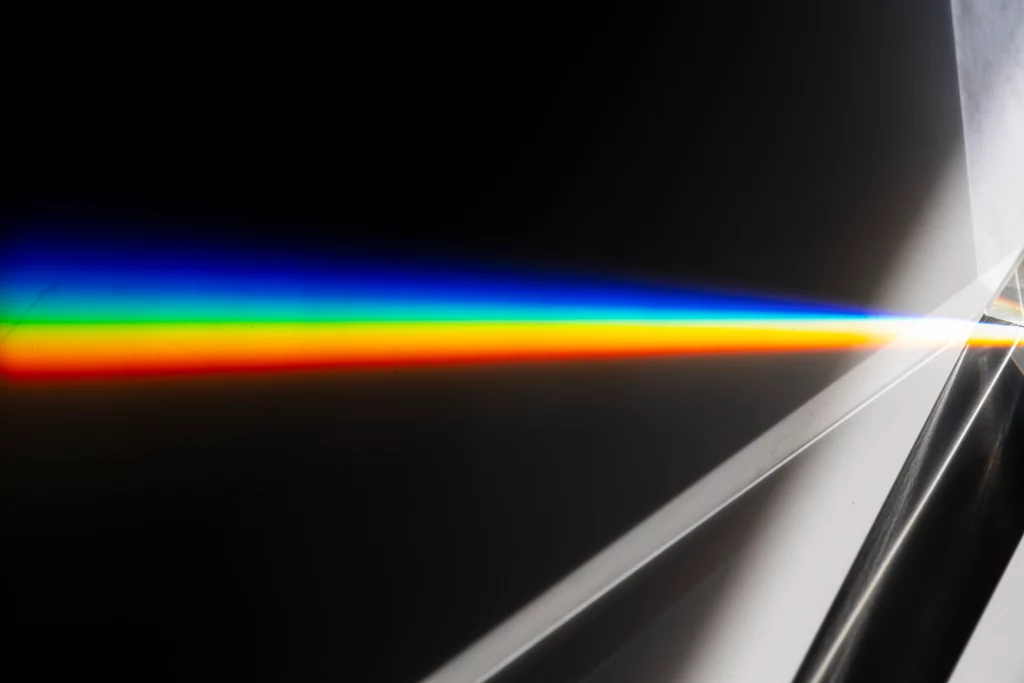

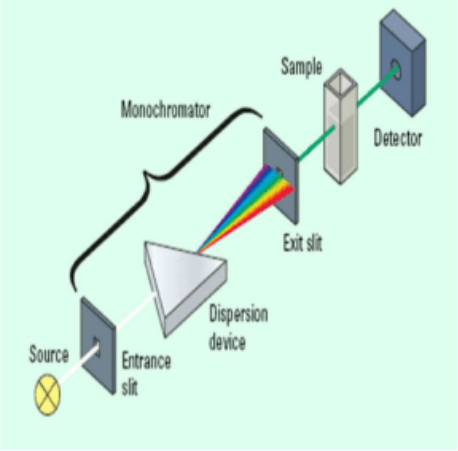

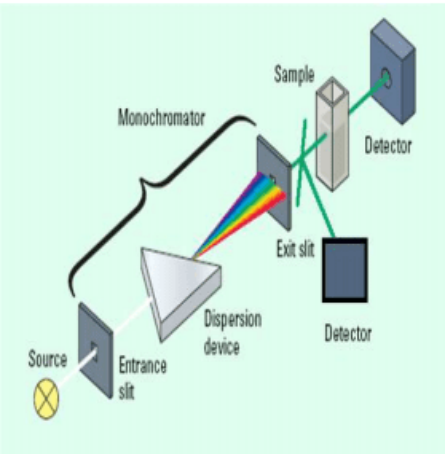

La espectrofotometría UV-Vis funciona en función de cómo la luz y la materia interactúan. Todo compuesto químico hace algo con la luz. Puede absorberlo, transmitirlo o reflejarlo en un cierto rango de longitudes de onda. Debido a esto, los investigadores pueden averiguar qué es una sustancia y cuánta de ella hay mirando sus espectros de absorbancia. Las partes principales de la máquina incluyen una fuente de luz, un monocromator, un punto para la muestra y un detector.

Tipos de fuentes de luz en instrumentos UV-Vis

Para buenas mediciones, una fuente de luz constante es muy importante. El tipo de lámpara que se utiliza decide qué parte del espectro se puede estudiar bien. Estas lámparas no’ t dura para siempre. Normalmente trabajan alrededor de 2.000 horas, por lo que los laboratorios necesitan planificar su cambio.

Lámparas de deuterio para el rango ultravioleta

Las lámparas de deuterio son perfectas para el trabajo UV. Emiten una luz continua y fuerte de 190-400 nm.

Lámparas de tungsteno-halógeno para el espectro visible

Estas lámparas proporcionan luz constante en todo el espectro visible e infrarrojo cercano, de 320 a 1100 nm.

Lámparas de arco de xenón y sus aplicaciones

Las lámparas de arco de xenón tienen una luz muy brillante y continua tanto en los rangos UV como visibles. Además, se encenden y apagan, lo que los hace excelentes para exploraciones rápidas y estudios de fluorescencia.

Espectrofotómetros de haz único

A la gente les gustan los diseños de haz único porque son simples y dejan pasar mucha luz. En esta configuración, la luz sigue un solo camino. Va desde la fuente, al monocromator, a través de la muestra y finalmente al detector.

Ventajas y limitaciones

Estos instrumentos son baratos y tienen un alto rendimiento de luz debido a su diseño más sencillo. En el pasado, fueron’ t como estable. Los cambios en la lámpara o el detector pueden causar problemas. Pero las cosas han cambiado. Los sistemas modernos de haz único son mucho mejores ahora. Tienen electrónica muy estable y software inteligente que corrige problemas. Como resultado, funcionan bastante bien y son buenos para muchos usos, incluyendo mediciones precisas utilizando la ley de Beer-Lambert.

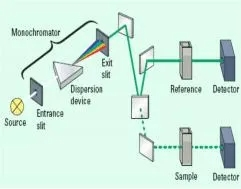

Espectrofotómetros de haz dividido

Los instrumentos de haz dividido son más precisos. Esto se debe a que utilizan un divisor de haz para apagar una pequeña parte de la luz como punto de referencia. Esta configuración ayuda a compensar cualquier inestabilidad en la lámpara. Esto conduce a una línea de base más estable durante mediciones largas. Por lo tanto, son un buen ajuste para los laboratorios de control de calidad que necesitan resultados sólidos sin comprar un sistema de doble haz más complejo.

Espectrofotómetros de doble haz

Los diseños de doble haz son una herramienta más avanzada. Pueden hacer un trabajo muy preciso.

Dos rutas ópticas y medición de referencia en tiempo real

Los espectrofotómetros de doble haz dividen la luz en dos caminos diferentes. Uno pasa por la muestra y el otro pasa por una referencia. ¿Cómo funciona? Por lo general, utiliza algo llamado helicóptero óptico. Es un sistema de espejo giratorio. Conmuta rápidamente la luz entre la trayectoria de muestra y la trayectoria de referencia. Luego, dirige ambos haces a un detector muy sensible. Este diseño elimina los problemas que podrían surgir si usas dos detectores diferentes. Algunas configuraciones de lujo también pueden usar un par de detectores para trabajos especiales.

Compensación y mayor precisión

Esta estructura proporciona corrección de ruido en tiempo real. Esto da resultados constantes y una precisión fotométrica sorprendente, a menudo alrededor de ±0,002 unidades de absorción. Estos sistemas son perfectos al mirar muestras nubladas o aquellos que no’ t dejar pasar mucha luz. En estos casos, incluso pequeños errores pueden realmente cambiar los resultados.

Comparación de diseños de haz único, dividido y doble

Elegir la configuración correcta realmente depende de lo que necesites. Tienes que pensar en la precisión, el costo y lo rápido que necesitas trabajar.

Estabilidad de la señal y mediciones a largo plazo

Los sistemas de doble haz son superiores cuando se trata de reducir el ruido. Mantienen la señal limpia con el tiempo. Esto es una gran ayuda para los estudios que observan cómo ocurre una reacción con el tiempo.

Adecuación para muestras de alta absorción

Las vigas dobles son excelentes para medir soluciones muy densas. En estas situaciones, la luz extravagante podría arruinar las lecturas. Estos instrumentos mantienen la luz extravagante extremadamente baja, a menudo especificada como < 0,01% T a 220 nm. Esto es una gran ventaja cuando se trabaja con tintes textiles.

Necesidades de calibración

Todas las máquinas deben ser comprobadas regularmente. Debes verificar cosas como la precisión fotométrica, la precisión de la longitud de onda (generalmente ±0,3 nm o mejor) y la luz extravagante. Esto se hace con materiales de referencia certificados (CRM) de lugares como Reagecon. Sigue normas como el capítulo general de la USP < 857> o Farmacopea Europea 2.2.25.

Costo vs. Rendimiento

Las unidades de haz único son más fáciles en la cartera. Sin embargo, los instrumentos de doble haz valen el precio más alto porque son tan analíticamente fuertes. Esto es especialmente cierto en laboratorios regulados o para investigaciones importantes.

Influencia del diseño óptico en aplicaciones de microespectrofotometría

La microespectrofotometría necesita una óptica muy buena. Esto se debe a que mira puntos tan pequeños.

Análisis de fibras y textiles

En la medicina forense, obtener un perfil espectral preciso puede identificar una sola fibra, incluso a nivel sub-nanogramo. Este trabajo es mucho más fácil con las configuraciones muy estables que se encuentran en instrumentos de doble haz conectados a microscopios.

Compatibilidad de colores y control de calidad

La huella digital espectral asegura que el color sea el mismo de un lote a otro. Esto es una necesidad en el branding textil. Incluso un pequeño cambio de color puede hacer que un producto sea rechazado.

Detección de trazas de colorantes o contaminantes

Con la microespectrofotometría, puede encontrar pequeñas cantidades de tintes u otras cosas no deseadas que puede’ Ver lo contrario. Esto ayuda a controlar la contaminación.

Para satisfacer estas difíciles necesidades analíticas, necesita instrumentos construidos sobre una base sólida de óptica excelente y ingeniería inteligente.

PERSEE: Instrumentación avanzada para los desafíos analíticos modernos

Perseguir es un actor importante en esta área. Hacen herramientas UV-Vis fuertes que están diseñadas para hoy’ laboratorios en muchas industrias diferentes. Con mucha experiencia, PERSEE utiliza ingeniería de primer nivel y fabricación certificada (ISO 9001:2015) para Ayuda a los laboratorios en todo el mundo necesitan instrumentos fiables.

Modelos destacados:

El Espectrómetro de haz dividido T7S ofrece un gran equilibrio entre rendimiento y costo. Es’ s bien adecuado para laboratorios universitarios y de control de calidad.

El T10DCSun verdadero instrumento de doble haz, tiene monocromatores dobles. Este diseño asegura que casi no hay interferencia de luz extravagante (típicamente < 0,001%T). Esto es imprescindible para analizar muestras con concentraciones bajas o que absorben mucha luz, lo que es común en el micromuestreo.

Ambos modelos tienen software fácil de usar. También tienen calibración de alineación automática y trabajan con estándares certificados para hacer que las pistas de auditoría sean más claras. Por lo tanto, pueden usarse en cualquier lugar, desde laboratorios de enseñanza hasta agencias ambientales.

Preguntas frecuentes:

Q1: ¿Cómo es la microespectrofotometría diferente de la espectroscopia UV-Vis regular?

R: La microespectrofotometría le permite estudiar las cosas a nivel microscópico. Puedes mirar fibras individuales o incluso células. Por el contrario, el UV-Vis regular analiza muestras líquidas más grandes. Esta habilidad especial lo hace esencial para trabajos donde necesitas ver detalles en un área muy pequeña.

Q2: ¿Por qué una configuración de doble viga es a menudo mejor para muestras textiles complejas?

R: Los espectrofotómetros de doble haz corregen los cambios del instrumento en tiempo real, lo que significa que obtiene mediciones más precisas. Esto es muy importante cuando se observan tejidos densos o complicados donde pequeños errores podrían llevarle a la conclusión equivocada sobre de qué está hecha la tela.

Q3: ¿Con qué frecuencia debo calibrar mi espectrofotómetro para el análisis de fibras?

R: La frecuencia con que necesita calibrar depende de cuánto utiliza la máquina, pero siempre debe hacerlo antes de cualquier trabajo crítico. Los cuerpos como el USP requieren comprobaciones regulares de la precisión de la longitud de onda (utilizando estándares como el óxido de Holmio) y la precisión fotométrica para asegurarse de que sus datos pueden confiar.