Spectrophotometers have become a key part of current analytical tools in various fields. These devices provide exact, steady, and harmless checks of absorbance, transmittance, and other light features, so they are vital for monitoring chemical, physical, and biological factors. A spectrophotometer works as an analytical device in nearly all kinds of chemical, biological, or life science labs.

Among worldwide companies in this field, Perseguir appears as a reliable maker of strong spectrophotometers, atomic absorption setups, and chromatography tools. Started in 1991, and with more than 30% of its staff in R&D, PERSEE runs as a fresh high-tech business committed to new ideas and helping customers everywhere. From UV-Vis kinds like the Espectrofotómetro T7 UV-vis to very sharp atomic absorption systems such as the AA990F Flame Atomic Absorption Spectrometer, PERSEE’s products are built for correctness, automatic work, and simple operation, which helps users in daily tasks.

Let’s explore how spectrophotometers drive efficiency and compliance across critical industrial applications, looking at their roles in different areas.

What Are the Most Critical Parameters Measured by Spectrophotometers?

Spectrophotometers meet a broad range of measurement needs, from basic to advanced ones.

Absorbance, Transmittance, Optical Density—How Do They Translate into Actionable Data?

Spectrophotometric checks rely mainly on Beer-Lambert’s Law. The amount of an analyte in a liquid can be found by using the absorbance or transmission traits of a substance based on wavelength. Absorbance shows how much light a sample takes in, while transmittance checks how much goes through. Optical density, often used in studies of germ growth, links right to cell amount or cloudiness, and this connection turns raw readings into useful info for decisions.

Newer types like the Espectrofotómetro UV-Vis T8DCS let users pick spectral bandwidths from 0.1 to 5 nm, which allows clear measurements for tough drug uses. These factors are key to keeping steady output, checking starting materials, and confirming end goods, so everything stays on track.

How Does Spectrophotometry Ensure Pharmaceutical Quality and Compliance?

Drug making needs a firm rule to follow. Spectrophotometers are a must for keeping both rule matching and quality checks in place.

How Is Spectrophotometry Used to Verify API Concentration and Purity?

In drug building and making, checking the amount of active pharmaceutical ingredients (APIs) cannot be skipped. All the different pharmacopoeia ask users to prove that their spectrophotometry gear works right for the listed work factors of Linearity, Wavelength, Bandwidth, and Stray Light. UV/Vis absorption shapes help spot dirt or broken-down parts by finding peaks at set wavelengths, and this spotting ensures clean and correct levels.

What Role Does It Play in Dissolution Testing?

Spectrophotometers also check how drugs come out over time through dissolution testing. By measuring absorbance as time goes on, they give insight into how well the drug works in the body and how the mix acts in fake body settings. Tools like the T7D UV-Vis handle movement checks and GLP rule handling, which makes them perfect for drug quality control spots.

How Does Spectrophotometry Safeguard Food and Beverage Quality?

Steady color and solid parts are big for trust in food and drink items.

Can It Accurately Detect Changes in Color and Appearance?

Yes. Spectrophotometers measure color shifts from handling or keeping, which looks the same across made batches. Colorimetry means checking and noting color, used in chemical checks, color fitting, color copying, and look studies, all to keep things looking good.

How Are Additives, Vitamins, or Contaminants Monitored?

UV/Vis spectrophotometry finds amounts of food boosters, such as ascorbic acid, or add-ons like keepers and colors. It also helps find bad stuff like heavy metals or bug killers left behind, which backs the right food label info and safety checks, so products stay safe and true.

How Do Spectrophotometers Enable Environmental Monitoring?

Earth labs use spectrophotometry to follow bad stuff in water, air, and dirt with good sharpness.

Which Parameters Are Measured in Water Testing?

Spectrophotometers find nitrate, phosphate, and ammonia amounts through UV/Vis methods. COD (Chemical Oxygen Demand) and TOC (Total Organic Carbon) get checked often to monitor wastewater outflow, which helps keep water clean.

Can Heavy Metals Be Detected Reliably?

Absolutely. With atomic absorption spectroscopy (AAS), small metals like lead, cadmium, and mercury can be found at parts-per-billion points. Atomic absorption and emission spectrophotometers usually spot elements and check their amounts. Types like the AA990F Flame AAS fit well for these jobs because of their good sharpness and pick power.

How Are Chemical Manufacturing Processes Optimized Through Spectrophotometry?

Work fields need now-time watching for better yields and less waste.

How Does Real-Time Monitoring Improve Process Control?

Spectrophotometers watch starting stuff run out or end stuff form by seeing absorbance changes in reactions. When linked to auto systems, off-paths can start fix steps right away, cutting stop time and keeping the product good.

What About Raw Material Inspection?

Light pattern marks help check incoming materials before they join the make line. This quick look stops dirt or swap problems that could cause high-cost take-backs or redo work, saving time and money.

How Are Cosmetic Formulations Evaluated Using Spectrophotometric Techniques?

Beauty items must hit hard safety rules while keeping a nice look.

How Are Ingredients Like Colorants or Sunscreen Agents Analyzed?

Colors and UV blocks get counted with UV/Vis spectrophotometry to make sure they stay in rule limits. Every chemical mix takes in, lets through, or bounces light (electromagnetic radiation) over set wavelength ranges, which makes light checks a great way to describe these mixes, ensuring they work right.

Can Spectrophotometry Simulate Product Stability Over Time?

Yes. By faking light or UV hits, spectrophotometers help guess light-break paths, key for shelf-time checks. Tools like the T9DCS UV-Vis give very low stray light work (≤0.00004%T @220nm), needed for these touchy looks.

Why Is PERSEE Considered a Trusted Partner for Analytical Solutions?

With years of R&D know-how and world help setup, PERSEE has set its name as a top in exact light study tools. T8DCS is a strong double beam spectrophotometer with a bandwidth pick from 0.1–5nm that keeps going. This bend lets users in fields, from pharma to oil chems, to best their check setups, making work smoother. Moreover, PERSEE gives full after-sales help like check kits (IQ/OQ/PQ), soft upgrades (UVWIN 6/GMP), training plans, and further help to keep tool correctness and rule match long-term, building strong ties.

Summary of Key Insights on Industrial Applications of Spectrophotometers

In areas like pharmaceuticals, food & beverage, environmental science, chemical processing, and cosmetics, spectrophotometers allow exact checks, boost make speed, ease rule match, and back fast picks from now data looks, helping businesses grow.

Preguntas frecuentes

Q1: How does a double...... 8211;beam spectrophotometer differ from a single...... 8211;beam model?

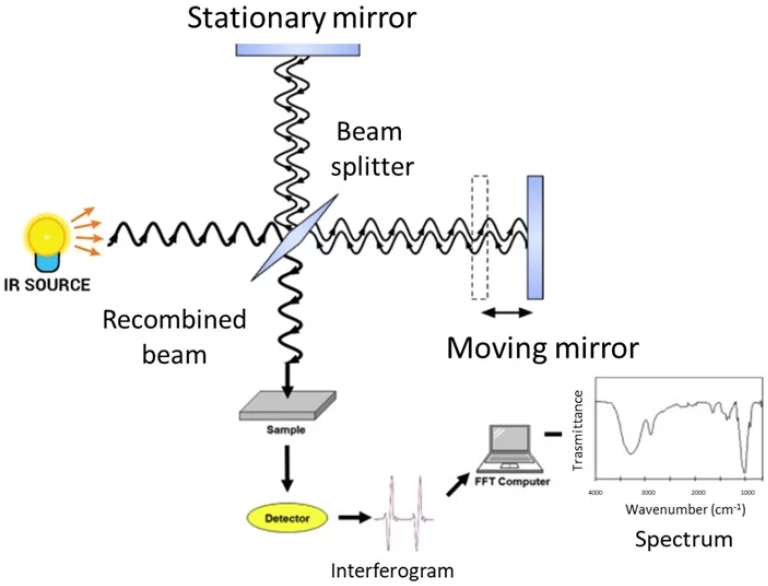

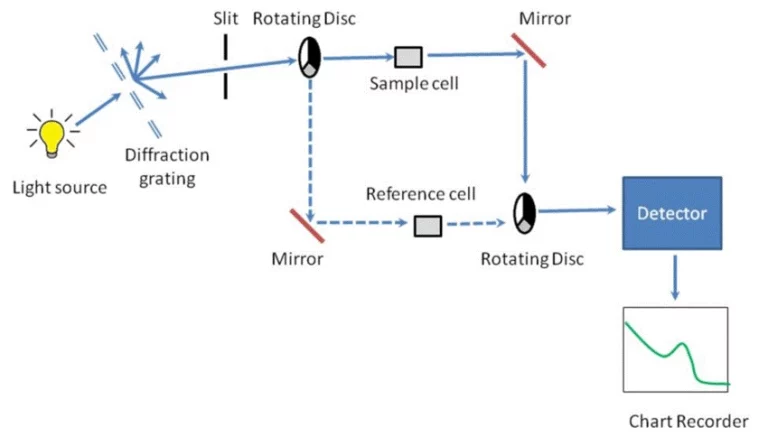

A1: double beam spectrophotometer splits the light source into two paths—one through the sample and one through a reference—allowing simultaneous comparison to minimize drift errors over time.

Q2: Can spectrophotometers detect multiple analytes simultaneously?

A2: Yes. Multi-wavelength scanning capabilities allow modern spectrophotometers to detect overlapping peaks from different compounds using deconvolution algorithms or derivative spectroscopy techniques.

Q3: What maintenance is required for long-term accuracy?

A3: Regular calibration using certified reference materials (CRMs), periodic lamp replacement (e.g., deuterium or tungsten), cleaning optical components like cuvettes/lenses, and software updates are essential for sustained performance accuracy over time.