Phổ quang học UV-VIS là một phương pháp phổ biến được sử dụng để đo và nghiên cứu các chất dựa trên cách chúng hấp thụ tia cực tím và ánh sáng nhìn thấy. Mặc dù kỹ thuật này rất quan trọng trong các phòng thí nghiệm trên nhiều lĩnh vực, nó có những khuyết điểm của nó. Biết nhược điểm của các công cụ UV-VIS là chìa khóa để cải thiện kết quả, phương pháp điều chỉnh tinh tế và chọn thiết bị phù hợp với nhu cầu của bạn.

Tổng quan về quang phổ UV-VIS

Phổ quang UV-VIS là trung tâm của các nghiên cứu hóa học hiện đại vì nó đơn giản, nhanh chóng và linh hoạt.

Nguyên tắc cơ bản của quang phổ UV-VIS

Trọng tâm của nó, quang phổ UV-VIS tuân theo định luật Beer-Lambert, liên kết lượng ánh sáng hấp thụ của một chất với lượng của nó. Phương pháp này đo lường bao nhiêu ánh sáng một hóa chất lấy vào hoặc để qua. Một chùm ánh sáng đi qua một mẫu, và công cụ đo ánh sáng xuất hiện. Các bộ phận chính bao gồm một nguồn ánh sáng, một thiết bị để chọn một màu ánh sáng, một bộ giữ mẫu và một máy dò để phân tích kết quả.

Sử dụng phổ biến trên khắp các ngành công nghiệp

Các công cụ UV-VIS được sử dụng trong phòng thí nghiệm thuốc để kiểm tra thuốc, trong phòng thí nghiệm môi trường để kiểm tra chất lượng nước, trong ngành công nghiệp thực phẩm để đo màu sắc và trong phòng thí nghiệm sinh học để đo protein.

Tầm quan trọng trong phòng thí nghiệm hiện đại

Công cụ này phổ biến trong hầu hết các phòng thí nghiệm hóa học, sinh học hoặc khoa học cuộc sống. Việc sử dụng rộng rãi của nó làm nổi bật nhu cầu hiểu cả điểm mạnh và điểm yếu của nó.

Giới hạn công cụ của công cụ UV-VIS

Mặc dù phổ biến và hữu ích của chúng, các công cụ UV-VIS có lỗi tích hợp có thể ảnh hưởng đến hiệu suất của chúng.

Giới hạn phạm vi bước sóng

Hầu hết các công cụ UV-VIS hoạt động trong phạm vi 190-1100 nm. Phạm vi này bỏ qua các phép đo ở các khu vực UV xa hoặc gần hồng ngoại. Các công cụ có thể đo ánh sáng nhìn thấy hoặc ánh sáng cực tím xuống đến khoảng 190 nm.

Độ nhạy cảm thấp cho các mẫu mỏng

Các máy dò tiêu chuẩn khó phát hiện các chất ở lượng rất nhỏ vì các tín hiệu ánh sáng quá yếu. Điều này làm cho UV-VIS ít hữu ích hơn để phát hiện dấu vết nhỏ bé trừ khi bạn sử dụng các bước bổ sung như tập trung mẫu trước.

Sự thay đổi cơ sở và các vấn đề ánh sáng lạc

Ngay cả các công cụ hàng đầu cũng có thể đối mặt với các vấn đề với đường cơ bản không ổn định và ánh sáng lạc lùng.

- Nguyên nhân của sự thay đổi baselineĐường cơ bản có thể dao động do thay đổi cường độ ánh sáng hoặc thay đổi nhiệt độ trong các bộ phận của công cụ.

- Tác động của Stray LightÁnh sáng lạc là ánh sáng không mong muốn đến với máy dò. Nó có thể làm rối kết quả, đặc biệt là khi đo độ hấp thụ cao. Các thử nghiệm cho các công cụ bao gồm kiểm tra độ chính xác hấp thụ, độ chính xác bước sóng, băng thông và ánh sáng lạc.

Những thách thức liên quan đến mẫu trong phân tích UV-VIS

Loại mẫu được kiểm tra cũng có thể gây ra các vấn đề ảnh hưởng đến độ chính xác và tính nhất quán.

Hiệu ứng ma trận và mẫu mây

Các mẫu mây hoặc đầy hạt phân tán ánh sáng thay vì hấp thụ nó đồng đều. Điều này vi phạm các quy tắc của Luật Beer-Lambert và dẫn đến kết quả sai.

Vấn đề hấp thụ dung môi

Một số chất lỏng, như ethanol dưới 210 nm, hấp thụ ánh sáng mạnh mẽ trong phạm vi UV. Điều này có thể che giấu tín hiệu của chất trừ khi bạn sử dụng một mẫu trống để sửa nó.

Lỗi chuẩn bị mẫu và tác động của chúng

Sai lầm như pha loãng sai, bong bóng không khí hoặc người giữ mẫu bị xước có thể gây ra lỗi lớn. Chuẩn bị mẫu tốt là rất quan trọng. Ví dụ, khi tạo tiêu chuẩn, ngay cả những sai lầm nhỏ trong cân hoặc trộn có thể dẫn đến sai lầm lớn trong kết quả.

Yếu tố hoạt động và môi trường ảnh hưởng đến hiệu suất

Bên cạnh các vấn đề thiết kế công cụ và mẫu, điều kiện bên ngoài và lỗi của con người cũng ảnh hưởng đến kết quả.

Tác động của nhiệt độ và độ ẩm

Thay đổi nhiệt độ phòng hoặc độ ẩm cao có thể ảnh hưởng đến thiết bị điện tử hoặc đường dẫn ánh sáng của công cụ. Điều này có thể gây ra các dòng cơ sở không ổn định hoặc đọc sai.

Lỗi hiệu chuẩn và thiếu bảo trì

Giống như tất cả các công cụ phòng thí nghiệm, các thiết bị UV-VIS cần kiểm tra thường xuyên để hoạt động tốt. Việc hiệu chuẩn kém với các tiêu chuẩn chất lượng thấp có thể làm tổn hại đến độ chính xác bước sóng hoặc tính nhất quán đo lường. Những kiểm tra này thường được yêu cầu bởi các quy tắc và tiêu chuẩn.

Lỗi nhà điều hành

Sự khác biệt trong cách mọi người xử lý các bộ giữ mẫu, chuẩn bị mẫu hoặc đọc kết quả có thể gây ra sự biến đổi. Điều này xảy ra ngay cả khi sử dụng cùng một công cụ.

Các vấn đề giải thích dữ liệu trong quang phổ UV-VIS

Đọc kết quả một cách chính xác đòi hỏi phải hiểu cách phổ hành vi ngoài việc so sánh chiều cao đỉnh cao.

Đỉnh hấp thụ chồng chéo

Hỗn hợp phức tạp thường tạo ra phổ chồng chéo, khiến việc xác định các bộ phận khó khăn. Bạn có thể cần các công cụ toán học tiên tiến hoặc các phương pháp tách như HPLC trước khi phân tích. Phổ phát sinh có thể giúp bằng cách thay đổi phổ về mặt toán học, nhưng điều này làm tăng sự phức tạp.

Không tuyến tính ở số lượng cao

Luật Beer-Lambert mong đợi một mối liên hệ thẳng giữa độ hấp thụ và lượng. Tuy nhiên, ở số lượng cao, điều này thất bại do tương tác phân tử hoặc ánh sáng lạc lùng.

- Nguyên nhân của sự lệch hướngLượng cao của một chất có thể thay đổi cách ánh sáng uốn cong hoặc gây ra sự hấp thụ lại, làm nghiêng kết quả.

- Pha loãng để cải thiện tính tuyến tínhLoãng các mẫu đến một phạm vi hấp thụ tốt (thường dưới 1,2 AU, lý tưởng là 0,2-1,0 AU) giúp giữ cho phản ứng đường thẳng cần thiết cho các phép đo chính xác.

Cách khắc phục các vấn đề phổ biến

Giải quyết các vấn đề này liên quan đến các phương pháp tốt hơn và các công cụ nâng cấp.

Tiêu chuẩn và kiểm tra công cụ thường xuyên

Tiêu chuẩn thường xuyên tuân theo các tiêu chuẩn như USP 857 hoặc hướng dẫn Ph.Eur. Những điều này đảm bảo công cụ hoạt động chính xác cho tính tuyến tính, bước sóng, băng thông và ánh sáng lạc.

- Các bước hiệu chuẩn được đề xuấtSử dụng vật liệu được chứng nhận như Holmium Oxide để kiểm tra bước sóng hoặc axit nicotinic để kiểm tra tính tuyến tính.

- Tầm quan trọng của vật liệu được chứng nhậnTiêu chuẩn phải được kiểm tra bằng các công cụ chất lượng cao theo tiêu chuẩn NIST hoặc ISO 17034.

Cải thiện các phương pháp chuẩn bị mẫu

Xử lý mẫu tốt giảm lỗi. Lọc các mẫu mây loại bỏ các hạt. Pha loãng các mẫu mạnh đảm bảo tính tuyến tính. Sử dụng các bộ giữ thạch anh phù hợp giữ cho con đường ánh sáng nhất quán.

Tăng độ chính xác với phần mềm

Phần mềm hiện đại giúp đỡ với các công cụ thông minh. Ví dụ, điều chỉnh dòng cơ bản có thể sửa chữa sự thay đổi trong các thử nghiệm dài, điều này rất tuyệt vời cho các nghiên cứu dựa trên thời gian.

Các công cụ nâng cao để khắc phục các vấn đề chính

Công nghệ mới đã tạo ra các công cụ UV-VIS tốt hơn để giải quyết các vấn đề cũ.

Các tính năng để tìm kiếm trong một công cụ UV-VIS chất lượng cao

Nhìn qua các tính năng cơ bản. Chọn các công cụ với thiết kế chùm kép, máy dò sắc nét và kiểm tra bước sóng tự động để có kết quả tốt hơn. Ví dụ, một hệ thống chùm đôi đo mẫu và chùm tham chiếu cùng một lúc. Điều này làm giảm sự thay đổi do sự thay đổi ánh sáng.

Ví dụ: Advanced Models

Một số dòng sản phẩm cung cấp các công cụ cho các nhu cầu khác nhau. Chúng bao gồm quang học chùm kép, sửa chữa dòng cơ bản tự động và khả năng quét sắc nét. Họ cung cấp kết quả chính xác trên các mẫu khác nhau.

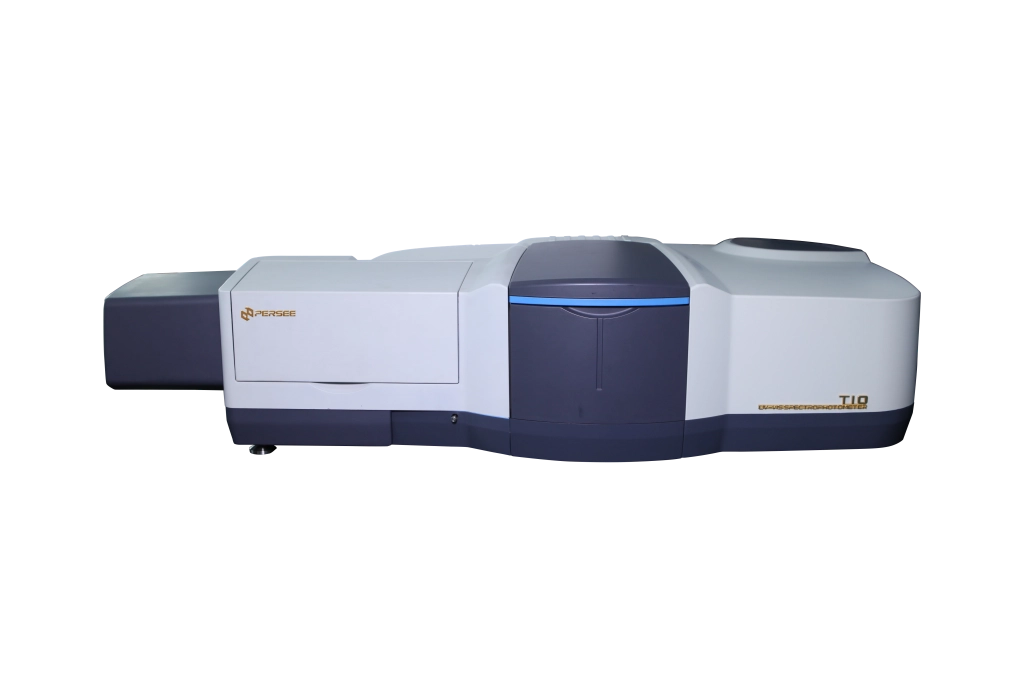

PERSEE: Một đối tác đáng tin cậy trong công cụ phòng thí nghiệm

Được thành lập với sự tập trung vào các ý tưởng mới, PERSEE được biết đến với các công cụ quang phổ chất lượng trên toàn thế giới. Nó phục vụ các trường học, ngành công nghiệp và phòng thí nghiệm chính phủ.

Phạm vi sản phẩm trong quang phổ phân tử

Sản phẩm của họ dao động từ các công cụ cơ bản đến tiên tiến.

- Dòng UV-Vis T7Tốt cho các trường học và phòng thí nghiệm kiểm soát chất lượng. Chúng cung cấp hiệu suất vững chắc mà không có các tính năng bổ sung.

- Dòng UV-Vis T10DCSĐược xây dựng cho các thiết lập khó khăn. Thiết kế chùm kép sửa chữa sự thay đổi đường cơ bản bằng cách điều chỉnh cho sự thay đổi ánh sáng trong thời gian thực. Điều này phù hợp với các nghiên cứu dài hạn hoặc nhiệm vụ cần sự ổn định cao và giới hạn phát hiện thấp.

Cam kết về chất lượng và hỗ trợ

Từ sản xuất được chứng nhận đến dịch vụ sau bán hàng hữu íchCông ty đảm bảo giá trị lâu dài cho khách hàng.

Tóm tắt các điểm chính

Phổ quang UV-VIS rất quan trọng nhưng không hoàn hảo. Những nhược điểm của nó bao gồm độ nhạy cảm thấp, các vấn đề ánh sáng lạc lùng, thay đổi cơ bản và thách thức chuẩn bị mẫu. May mắn thay, những điều này có thể được sửa chữa. Tiêu chuẩn thường xuyên, phần mềm thông minh, quy trình làm việc tốt hơn và các công cụ tiên tiến đảm bảo kết quả chính xác và đáng tin cậy mỗi lần.

Câu hỏi thường gặp

Q1: Những mẫu nào hoạt động tốt nhất cho quang phổ UV-VIS?

A: Mẫu chất lỏng rõ ràng với lượng chất trung bình là lý tưởng. Chúng cung cấp các tín hiệu hấp thụ mạnh mẽ mà không có các vấn đề phân tán phổ biến trong các mẫu mây.

Q2: Tôi nên hiệu chuẩn công cụ UV-VIS của mình bao lâu?

A: Điều chuẩn thường xuyên là chìa khóa - thường trước mỗi bộ kiểm tra hoặc hàng tuần, tùy thuộc vào việc sử dụng. Điều này đáp ứng các tiêu chuẩn như USP 857 hoặc yêu cầu Ph.Eur.

Q3: Tôi có thể sử dụng tiêu chuẩn của bất kỳ thương hiệu nào với công cụ của tôi không?

A: Vâng. Tiêu chuẩn chất lượng cao hoạt động với bất kỳ công cụ UV-VIS nào, miễn là chúng đáp ứng các quy tắc theo dõi như chứng nhận NIST. Điều này đảm bảo họ hoạt động trên các thương hiệu khác nhau.