Trong thế giới ngày nay’ Hóa học phân tích, các phương pháp đặc biệt như quang phổ hấp thụ nguyên tử (AAS), quang phổ khối lượng plasma kết nối cảm ứng (ICP-MS) và quang phổ phát xạ quang học (OES) là hoàn toàn cần thiết. Chúng giúp chúng ta tìm và đo một lượng rất nhỏ các yếu tố. Một phần thực sự quan trọng của các phương pháp này là khí argon. Nó đóng một vai trò rất lớn. Nó đảm bảo các phép đo là chính xác, đáng tin cậy và không bị gián đoạn. Nếu bạn làm việc với một máy quang phổ, bạn cần biết tại sao khí argon được sử dụng. Kiến thức này là chìa khóa để có được kết quả tốt nhất và đảm bảo dữ liệu của bạn là hợp lý.

Vai trò của khí argon trong kỹ thuật quang phổ

Argon thực hiện nhiều công việc khác nhau trên các phương pháp quang phổ khác nhau. Điều này là do tính chất vật lý và hóa học đặc biệt của nó.

Đặc điểm của Argon làm cho nó lý tưởng cho quang phổ

Argon là một loại khí quý giá. Nói cách đơn giản, điều này có nghĩa là nó không phản ứng hóa học trong các tình huống bình thường. Bởi vì’ s rất ổn định, nó ngăn chặn những thay đổi hóa học không mong muốn xảy ra trong khi phân tích đang diễn ra. What’ Hơn nữa, argon có trọng lượng nguyên tử khá nặng và không phải là chất dẫn nhiệt tốt. Những tính năng này làm cho nó hoàn hảo để giữ plasma ở nhiệt độ rất cao, và nó làm điều này mà không phản ứng với các bộ phận của mẫu hoặc chính máy.

Lợi ích của việc sử dụng khí bất động trong các dụng cụ phân tích

Sử dụng một khí không phản ứng như argon là một sự giúp đỡ lớn. Nó giữ cho bên trong của thiết bị rất ổn định. Sự ổn định này làm giảm tiếng ồn nền. Nó cũng làm giảm khả năng ô nhiễm từ các khí trong không khí, chẳng hạn như oxy hoặc nitơ. Kết quả là các phép đo được chính xác hơn nhiều. Điều này đặc biệt đúng khi tìm kiếm một lượng nhỏ của một chất.

Khí argon trong quang phổ lượng plasma kết nối cảm ứng (ICP-MS)

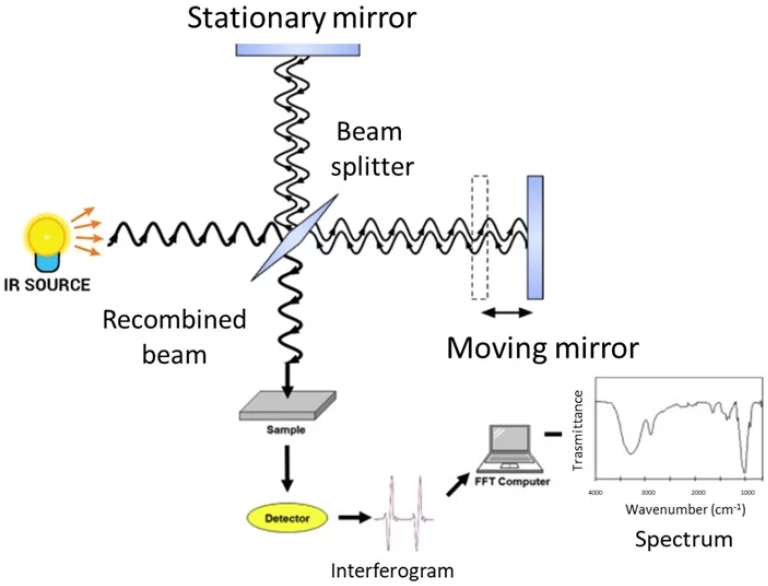

ICP-MS phụ thuộc rất nhiều vào argon để hoạt động tốt. Khí giúp tạo ra plasma. Nó cũng làm cho ion hóa hiệu quả hơn.

Chức năng của Argon trong Plasma Generation

Trong ICP-MS, khí argon được gửi vào ngọn đuốc. Ở đó, một trường điện từ ion hóa nó. Quá trình này tạo ra một plasma. Một plasma là một trạng thái vật chất với một lượng năng lượng rất lớn, và nhiệt độ của nó có thể tăng lên đến 10.000 K. Nhiệt độ đáng kinh ngạc này đủ mạnh để phá vỡ mẫu’ các phân tử thành các nguyên tử và ion cơ bản của chúng.

Làm thế nào Argon tăng cường hiệu quả ion hóa

Plasma argon tạo ra một nơi có nhiều năng lượng. Môi trường mạnh mẽ này đảm bảo rằng ngay cả các yếu tố khó ion hóa cũng được biến thành ion một cách hiệu quả. Kết quả là, điều này làm cho máy quang phổ khối lượng tốt hơn trong công việc của nó. Nó trở nên chính xác và nhạy cảm hơn khi tìm thấy một lượng nhỏ các yếu tố.

Tác động đến độ nhạy cảm và giới hạn phát hiện

Argon tạo ra một môi trường plasma sạch sẽ và ổn định. Bởi vì điều này, nó làm giảm đáng kể giới hạn phát hiện cho nhiều yếu tố. Vì vậy, điều đó làm cho ICP-MS trở thành một trong những phương pháp nhạy cảm nhất mà chúng ta có sẵn ngày nay.

Áp dụng Argon trong quang phổ hấp thụ nguyên tử (AAS)

Argon’ Công việc của bạn đặc biệt quan trọng trong các hệ thống AAS sử dụng lò graphite.

Sử dụng Argon trong lò Graphite AAS

Trong lò graphite AAS (GFAAS), một mẫu được làm nóng bên trong một ống graphite. Điều này biến chất phân tích thành nguyên tử. Khí argon chảy qua hệ thống trong toàn bộ quá trình sưởi ấm.

Bảo vệ ống graphite khỏi oxy hóa

Các ống graphite có thể bị hư hại bởi oxy ở nhiệt độ cao. Argon’ thiên nhiên không phản ứng giúp ngăn chặn điều này. Nó đẩy oxy ra khỏi đường. Do đó, nó bảo vệ ống graphite khỏi bị oxy hóa, giúp các bộ phận đắt tiền kéo dài lâu hơn và giữ cho hiệu suất ổn định.

Sự ổn định của môi trường nguyên tử hóa

Argon cung cấp một khí quyển không có oxy bên trong lò. Điều này xảy ra trong quá trình nguyên tử hóa. Vì vậy, nó đảm bảo rằng máy chỉ đo các nguyên tử phân tích. Không có sự can thiệp từ các hạt oxy hóa hoặc các vật tạo ra bởi sự đốt cháy.

Nâng cao an toàn và hiệu suất thông qua giám sát dòng chảy Argon

Điều quan trọng là theo dõi tỷ lệ lưu lượng argon. Điều này giúp giữ cho điều kiện lò chỉ đúng đắn. Nếu tốc độ dòng chảy thay đổi, tín hiệu có thể trở nên không ổn định. Nó thậm chí có thể làm hỏng các bộ phận do quá nhiều nhiệt hoặc oxy hóa.

Tầm quan trọng của khí argon trong quang phổ phát xạ quang học (OES)

Các phương pháp OES cũng nhận được lợi ích lớn từ việc sử dụng khí argon. Điều này đặc biệt đúng khi phân tích các mẫu kim loại rắn bằng các phương pháp xả tia lửa.

Vai trò trong quang phổ phát xạ quang Spark

Spark OES sử dụng tia lửa điện để kích thích các nguyên tử. Lửa cháy này xảy ra giữa hai điện cực. Toàn bộ sự kiện diễn ra trong một buồng kín đầy khí argon.

Tạo một bầu không khí kích thích vô tính

Argon trong buồng đảm bảo rằng sự kích thích xảy ra sạch sẽ. Không có sự can thiệp từ các khí phản ứng trong không khí, chẳng hạn như oxy hoặc nitơ. Điều này dẫn đến phổ phát xạ rõ ràng hơn nhiều.

Phòng ngừa can thiệp từ các chất ô nhiễm trong không khí

Argon chảy qua buồng liên tục. Dòng chảy này đẩy ra bất kỳ chất ô nhiễm nào. Trước hết, điều này làm giảm tiếng ồn nền. Điều gì’ Hơn nữa, nó làm cho các phép đo cho các nguyên tố vi lượng chính xác hơn nhiều.

Đóng góp vào phát hiện nguyên tố UV chính xác

Một số đường quang phổ trong phạm vi tia cực tím rất nhạy cảm với sự can thiệp. Một khí quyển vô động với argon rất tinh khiết là cần thiết để đo các đường này một cách đáng tin cậy. Điều này rất quan trọng khi bạn đang cố gắng phát hiện các yếu tố như kẽm hoặc magiê ở mức dưới một phần trên triệu. Ví dụ, dòng 213,8 nm được sử dụng để tìm kẽm.

Yêu cầu về độ tinh khiết và ảnh hưởng đến độ chính xác phân tích

Không phải tất cả khí argon đều giống nhau. Mức độ tinh khiết của nó có tác động trực tiếp đến kết quả của tất cả các phương pháp quang phổ.

Mức độ tinh khiết được đề xuất cho các kỹ thuật khác nhau

Bạn nên sử dụng argon tinh khiết cao cho ICP-MS và GFAAS. Điều này thường là 99,999% tinh khiết. Những phương pháp này rất nhạy cảm với bất kỳ chất ô nhiễm nào. Đối với các công việc ít đòi hỏi hơn, khí tinh khiết thấp hơn có thể hoạt động, nhưng chúng có thể làm cho kết quả ít chính xác hơn theo thời gian.

Hậu quả của việc sử dụng khí argon tinh khiết thấp

Điều gì sẽ xảy ra nếu argon’ T tinh khiết? Những thứ như độ ẩm hoặc oxy có thể gây ra vấn đề. Chúng có thể phản ứng với các điện cực trong OES tia lửa, làm mòn chúng và tạo ra các tín hiệu lộn xộn. Điều này ảnh hưởng đến mức độ kết quả có thể lặp lại. Ngoài ra, các chất gây ô nhiễm từ argon không tinh khiết có thể tích tụ trên ống kính hoặc gương bên trong dụng cụ. Điều này làm giảm lượng ánh sáng đi qua và có nghĩa là cần bảo trì nhiều hơn.

Hệ thống giới thiệu mẫu và vai trò của khí

Trước khi phân tích có thể bắt đầu, các mẫu cần được đưa vào hệ thống. Chúng được biến thành phun tinh tế, hoặc aerosol.

Sương mù và vận chuyển aerosol

Cách tạo ra aerosol phụ thuộc vào phương pháp. Trong ICP-MS, một dòng argon được sử dụng. Nó phun mẫu chất lỏng thành một phun mịn và mang nó đến ngọn đuốc huyết tương. Mặt khác, hệ thống Flame AAS làm điều đó khác nhau. Họ thường sử dụng một dòng chảy nhanh của một khí oxy hóa, như không khí nén, để kéo mẫu lên và làm sương mù vào ngọn lửa.

Thiết kế ngọn đuốc và cấu hình đa luồng để ổn định plasma

Hôm nay’ ngọn đuốc ICP có thiết kế với nhiều kênh. Các thiết kế này sử dụng các dòng argon riêng biệt để làm mát, hỗ trợ và cho máy phun. Thiết lập này giúp ổn định plasma’ hình dạng và nhiệt độ. Cuối cùng, điều này đảm bảo bạn nhận được kết quả nhất quán mỗi khi bạn chạy một bài kiểm tra.

PERSEE: Nhà sản xuất công cụ phân tích đáng tin cậy

Nhu cầu thiết bị chính xác ngày càng tăng. Bởi vì điều này, các nhà sản xuất như PERSEE đã được biết đến như là các công ty đáng tin cậy dành riêng cho thiết kế và hiệu suất tuyệt vời.

Tổng quan về dòng sản phẩm của PERSEE cho phân tích quang phổ

PERSEE cung cấp một loạt các máy tiên tiến được làm cho phân tích nguyên tố. Sản phẩm của họ bao gồm cả lửa và lò graphite quang phổ hấp thụ nguyên tử.

Tính năng và ứng dụng máy phổ hấp thụ nguyên tử A3G

Các Mô hình A3G là một hệ thống linh hoạt. Nó có cả một máy phóng ngọn lửa và một lò graphite. Nó cung cấp hiệu suất vững chắc trong nhiều tình huống khác nhau. Ví dụ, nó được sử dụng trong thử nghiệm môi trường, kiểm tra an toàn thực phẩm và nghiên cứu kim loại. Bộ phận lò graphite đặc biệt được hưởng lợi từ các hệ thống tích hợp được thiết kế để sử dụng an toàn và kiểm soát chính xác các khí inert như argon.

img.A3G Atomic Absorption Spectrometer.webp

Khả năng hệ thống hấp thụ nguyên tử lửa AA990F

Các Aa990f được xây dựng chỉ cho các thử nghiệm dựa trên ngọn lửa. Nó cung cấp độ nhạy cảm cải thiện. Nó làm điều này thông qua kiểm soát chính xác tỷ lệ nhiên liệu (acetylene) và khí oxy hóa (khí / oxyt nitơ) và một hệ thống giới thiệu mẫu rất hiệu quả.

Cam kết với độ chính xác, an toàn và đổi mới

PERSEE sử dụng công nghệ mới nhất cùng với kiểm soát chất lượng nghiêm ngặt. Điều này đảm bảo mọi thiết bị cung cấp kết quả ổn định. Đồng thời, nó giữ cho người vận hành an toàn với các hệ thống quản lý khí thông minh. Các hệ thống này bao gồm giám sát dòng chảy tự động và báo động bảo vệ chống rò rỉ.

Tóm tắt và Key Takeaways

Bạn có thể’ t đánh giá quá mức tầm quan trọng của argon trong các kỹ thuật quang phổ chính xác cao. Nó ổn định plasma trong hệ thống ICP-MS. Nó bảo vệ lò graphite trong GFAAS. Nó cũng tạo ra môi trường không phản ứng cần thiết cho đọc OES tia lửa chính xác. Chọn đúng khí và đảm bảo nó’ s tinh khiết là cơ bản để giữ các dụng cụ chạy trong một thời gian dài, cải thiện độ nhạy và giảm sự can thiệp. Các nhà sản xuất đáng tin cậy như PERSEE xây dựng các công cụ của họ với nhu cầu này trong tâm trí. Do đó, chúng đảm bảo công việc an toàn và đáng tin cậy với các khí đúng cho mỗi công việc.

Câu hỏi thường gặp:

Q1: Tại sao argon tinh khiết cao cần thiết cho ICP-MS và GFAAS?

A: Bạn cần argon tinh khiết cao để có lượng ô nhiễm nhỏ nhất có thể khi tạo ra plasma hoặc trong quá trình nguyên tử hóa. Điều này ảnh hưởng trực tiếp đến độ chính xác của phân tích của bạn. Bất kỳ tạp chất nào có thể tạo ra tiếng ồn nền. Chúng cũng có thể can thiệp vào việc phát hiện ở mức rất thấp. Điều này có thể làm hỏng kết quả của bạn, đặc biệt là khi bạn đang phân tích một lượng kim loại nhỏ xuống đến phần trên một nghìn tỷ.

Q2: Các khí inert khác có thể thay thế argon trong quang phổ không?

A: Có thể sử dụng các khí quý giá khác. Ví dụ, heli hoặc nitơ có thể được sử dụng cho một số công việc nhất định. Tuy nhiên, argon cung cấp sự pha trộn tốt nhất của chi phí tốt, khả năng sẵn có dễ dàng và tiềm năng ion hóa phù hợp để tạo ra plasma ổn định trong ICP. Đối với GFAAS, nó cung cấp sự bảo vệ tuyệt vời với giá tốt. Điều này làm cho nó trở thành sự lựa chọn bình thường cho công việc phổ biến nhất.

Q3: Làm thế nào để PERSEE đảm bảo việc sử dụng an toàn khí trong các dụng cụ của họ?

A: PERSEE đặt các tính năng an toàn vào máy của mình, như A3G và AA990F AAS. Chúng bao gồm bộ điều khiển dòng chảy tự động theo dõi tỷ lệ cung cấp khí trong thời gian thực. Điều này đảm bảo hoạt động ổn định và cũng ngăn chặn các mối nguy hiểm từ quá nhiều áp lực hoặc rò rỉ. Các tính năng như thế này làm cho mọi thứ an toàn hơn cho người dùng và cũng làm cho phân tích đáng tin cậy hơn khi bạn đang làm việc với bể khí áp suất.