1. Panoramica del metodo

Dopo un trattamento appropriato, il campione viene atomizzato in un forno di grafite e l'assorbinza viene misurata a 283,3 nm. All'interno di un certo intervallo di concentrazione, l'assorbimento del piombo è proporzionale al suo contenuto e la quantificazione viene eseguita confrontando con una serie standard.

2. Strumenti e Reagenti

2.1 Strumenti e attrezzature

2.1.1 Strumenti di prova

| Nome | Quantità | Requisiti tecnici | Accessori |

|---|---|---|---|

| Micropipetta | 1 ciascuno | 100 μL ~ 1000 μL, 1000 μL ~ 5000 μL, 5 ~ 50 μL | |

| Flacone volumetrico | Diversi | 100 ml |

2.1.2 Attrezzature di pretrattamento

| Numero di serie. | Nome | Quantità | Requisiti tecnici | Accessori |

|---|---|---|---|---|

| 1 | Micropipetta | 1 ciascuno | 100 μL ~ 1000 μL, 1000 μL ~ 5000 μL, 5 ~ 50 μL | |

| 2 | Flacone volumetrico | Diversi | 100 ml |

2.2 Reagenti

2.2.1 Reagenti

| Numero di serie. | Nome | Requisiti tecnici | Osservazioni |

|---|---|---|---|

| 1 | Acido nitrico | grado MOS |

2.3 Norme di riferimento

2.3.1 Soluzioni stock

| Numero di serie. | - No, no, no. | Nome | Requisiti tecnici | Osservazioni |

|---|---|---|---|---|

| 1 | GBW 08619 | Sostanza standard di soluzione a singolo elemento di piombo | 1000 μg/ml | Istituto Nazionale di Metrologia, Cina |

3. Procedure operative

3.1 Elaborazione del campione

3.1.1 Preparazione della soluzione di prova

Prendere 100 mL di campione d'acqua in un fiasco volumetrico, aggiungere 0,5 mL di acido nitrico, e mescolare bene. Eseguire un test vuoto accanto al campione.

3.1.2 Preparazione di soluzioni standard

-

Preparazione della soluzione intermedia standard di piombo: soluzione standard di piombo (1,0 μg/mL): pipettare accuratamente 0,1 mL di soluzione standard di piombo (1000 μg/mL) in un fiasco volumetrico da 100 mL, aggiungere 0,5 mL di soluzione di acido nitrico, diluire fino al marchio e scuotere bene.

-

Preparazione della serie standard di piombo: pipettare con precisione 0,0, 0,1, 0,2, 0,3 e 0,4 mL di soluzione standard di piombo (1,0 μg/mL) rispettivamente in fiastrini volumetrici da 10 mL. Aggiungere 0,5 mL di soluzione di acido nitrico a ciascuno, diluire fino al marchio e ottenere soluzioni standard di piombo con concentrazioni di 0,0, 10,0, 20,0, 30,0 e 40,0 ng / mL.

3.2 Prova del campione

- Condizioni di prova Condizioni di riferimento per la rilevazione dello spettrofotometro di assorbimento atomico in forno a grafite

| Elemento | Piombo |

|---|---|

| Lunghezza d'onda (nm) | 283.3 |

| Larghezza di banda spettrale (nm) | 0.4 |

| Corrente della lampada dell'elemento (mA) | 2.0 |

| Metodo di correzione dello sfondo | Lampada al deuterio |

Programma di riscaldamento forno grafite

| Passo | Procedura | Temperatura (℃) | Tempo di rampa (s) | Tempo di attesa (s) |

|---|---|---|---|---|

| 1 | Asciugatura | 120 | 10 | 10 |

| 2 | Ashing | 450 | 10 | 10 |

| 3 | Atomizzazione | 1800 | 0 | 2 |

| 4 | Pulizia | 1900 | 1 | 2 |

- Determinare l'assorbimento di soluzioni standard, soluzioni di prova vuote e soluzioni di prova in sequenza. Sottrarre l'assorbinza della soluzione standard zero dall'assorbinza di ogni soluzione standard. Traccia una curva di lavoro con la concentrazione di massa come abscissa e la corrispondente assorbianza come ordinata. In base all'assorbinza misurata della soluzione di prova, individuare la concentrazione di massa di piombo dalla curva di lavoro.

3.3 Calcolo dei risultati

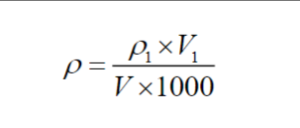

Formula:

Dove:

ρ — Concentrazione massica di piombo nel campione d'acqua, in milligrammi per litro (mg/L);

ρ1Concentrazione massica di piombo nel campione d'acqua ottenuto dalla curva standard, in nanogrammi per millilitro (ng/mL);

V1 — Volume della soluzione del campione da determinare, in millilitri (mL);

V — Volume del campione d'acqua originale, in millilitri (mL);

1000 — Fattore di conversione.