スペクトロスコピーは現在の光光光光光分分光鏡学は分光光光鏡学は光光光光光光光光光光光光光分分分光光光分分分分光光光分その用途は幅広く,法医から製造品質管理までのすべてのことを助けます.使用されているさまざまな器具のうち,単一ビームUV-Vis分光度計は特別です.なぜ?シンプルな設計、手頃な価格、および吸収率と透射率をどれだけよく測定するのです。このデバイスの重要な部分は、光源であり、スペクトラルデータの精度と信頼性に直接影響を与える。この基本原理やその他の基本原理を理解することは、分析結果を改善するための鍵です。この記事では、これらの基本的な技術を探求します。What’さらに,現代的な器具を例として使用して,纤維や纤ささささらに,ささささらに,さささささらに,ささささらに,ささささらに,ささささらに,ささささら

Fiber and Textile Analysis における分光鏡学の基礎

スペクトロスコピーは,電磁放射線にどのように反応するかに基づいて,物質を傷つけずに検査する方法を提供します.この反応は重要な詳細を示しています。分子構造、化学構成、物理的特徴について教えています。

光分光分析における光物質相互作用の役割

光が物質に打つと、吸収され、通過したり、反射することができます。UV-Visスペクトロスコピーはこれに焦点を当てています。この方法では、吸収率は波長に対して測定されます。これは、これらの化合物の存在と量を判断するのに役立ちます。

材料特徴に使用される分光鏡の種類

異なる種類の分光鏡は光光光光光光光光異異なる種類の光光光光光異異なる種類の分光光光光光光光光光光光異異なる種類の分光これらには、UV-Vis吸収分光学、赤外線(IR)分光学、ラマン分光学、原子分光学が含まれています。それぞれの方法には特別な利点があります。たとえば,染料,添加物,ポリマー,微量元素を見つけるために素晴らしいです.

正確な色と成分測定の重要性

織物製造において,色の均一性と化学的メイクアップは非常に重要な要因です.まず、スペクトロスコピー方法は、染料が均等に広がっていることを確認します。また、完成品に有害物質が見つかりません。

纤維検査のための微分光学技術

Microspectrophotometry は二つの技術の組み合わせです。顯微鏡と分光鏡分析を融合します。目的は、単一のファイバーのような小さなサンプルを見ることです。

法医学と産業における微分光光学の応用

この技術は法医学において非常に活用されています。そこでは、犯罪現場からのファイバー証拠を容疑者からの資料と比較するために使用されます。産業界では,微鏡レベルで欠陥や違いを見つけることによって品質保証に役立ちます.

機器構成と光学要件

マイクロスペクトロフォトメーターには 最高品質の光学が必要ですこれらの光学は非常に小さなサンプルスポットに光を集中させることができなければなりません,しばしば1マイクロメートル (µm) の空間解像度で空空空間解像度がこれこれっきりです.同時に、幅広い波長で高いスペクトラル解像度を維持する必要があります。

トレース証拠のためのマイクロスペクトロフォトメトリーを使用する利点

マイクロスペクトロフォトメトリーの大きなプラスは、痕跡証拠の非破壊的な検査を可能にすることです。サンプルを変更したり使ったりしません。これは、裁判所で証拠を許可するための重要な特徴であり、後でさらなる検査を行う選択肢です。

単一ビームUV-Vis分光光度計における光源の機能

UV-Vis分光度計では,信頼性の高い吸収データを得るために光源が基本的です.

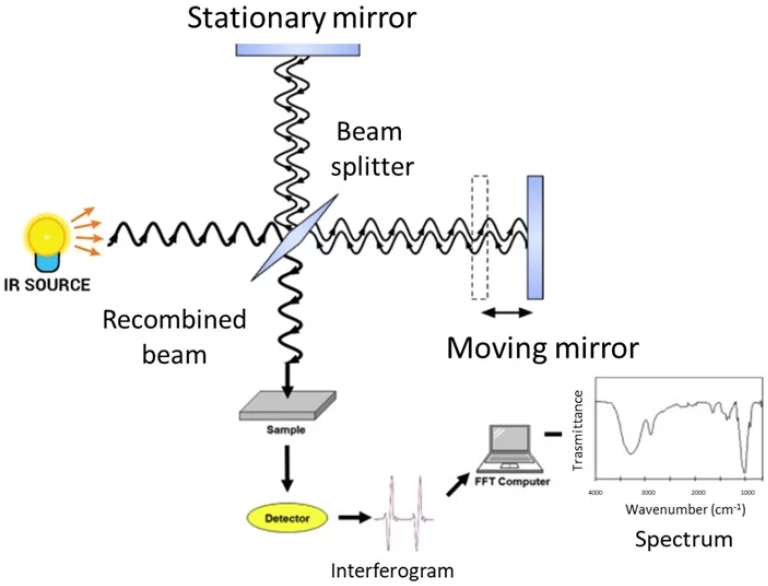

光源が吸収度測定を可能にする方法

光源の主な仕事は、紫外線と可視波長を通じて安定した放射線の流れを送ることです。この放射線は、サンプルに到達する前に特定の波長を引き出すモノクロメーターを通過します。その後,検出器はサンプルを通過する光の量を測定し,吸収スペクトルを作成します.

ドイテリウムおよびタングステンランプの特徴

スペクトロフォトメーターには通常、全スペクトルをカバーするための2種類のランプがあります。彼らは紫外線領域(通常190-400nm)のためにデューテリウムランプを使用します。可視および近赤外線領域(通常350-1100 nm)では、タングステン・ハロゲンランプを使用します。

波長カバージョンと安定性に関する考慮事項

ドイテリウムランプは深紫外線範囲で安定した強力な出力を与えます。一方、タングステンランプは可視区域で強力な放出を持っています。器具は設定された波長でランプ間を自動的に切り替える。これにより、フルスペクトルのカバーが滑らかになります。

測定精度と再現性への影響

ランプの安定性は,ベースラインの漂移と測定の繰り返し性に直接影響を与えています.ランランランプの安定した光源はランランランランプの安定した光源がランランランランプの安定した光源がランランランランプレートの安定した光源が必要です.また,信号の変化は機械ではなくサンプルから来ることを確認します.

シングルビームとダブルビームUV-Visスペクトロフォトメーターの比較

シングルビームおよびダブルビームスペクトロフォトメーターの設計と機能的違いを知ることが重要です.特定の仕事に適した道具を選ぶのに役立ちます。

機器設計における構造的違い

シングルビームスペクトロフォトメーターは、すべての光を1つの光経路を通じて送ります。まず、ベースライン読み取りは参照(空白)で行われます。その後、サンプルの読み取りが行われます。対照的に、ダブルビームデザインは異なっています。彼らは光を同時に2つの経路に分割します:1つは参照を通り、もう1つはサンプルを通ります。

各構成の利点と制限

シングルビームシステムは,多くの日常の仕事に最適な選択です.機械的には複雑で小さく 安いものです過去には、一つの大きな弱点があった。これは、ランプの変更のために起こった可能な時間の経過による基準線の漂移でした。一方、ダブルビーム機器は自然にこのような問題を解決します。これを同時に測定することにより、より安定性が高まるが、より高価で複雑になります。

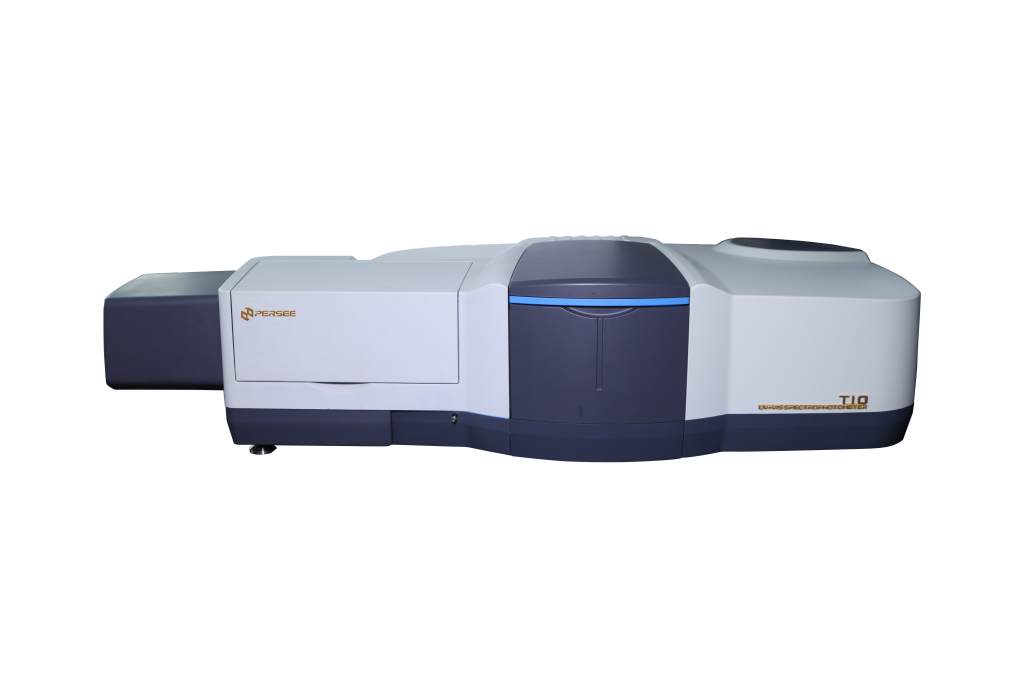

しかし、状況は変わりました。現代のエンジニアリングは、単一ビーム設計の古い問題をほとんど解決しています。例えば、楽器のような PERSEE’s T6U UV Vis分光光計 セルフタイマー付き非常に安定したデュアルランプシステムを使用します。これにより、光は安定している。したがって,優れたベースライン安定性を提供し,産業試験や学校の実験室のために信頼性が高く,手頃な価格の選択肢になります.

UV-VIS分光鏡検査の使用

UV-Visスペクトロスコピーは,染染染料量,染染染料処理,不純物,または破壊による損傷について迅速に情報を提供します.これらのすべては、織物品質管理に不可欠です。

染料、添加物、および不純物の検出

特定の染色体に一致するスペクトラルピークは,布を染める際に使用される色素を特定することができます.残りの化学物質も見つけることができます。

吸収ピークによる定量的分析

ビール・ランバート法則を使用することで、UV-Visスペクトロスコピーはサンプル内の化合物の量を正確に測定できます。法律は次のように書かれています。

A=εbc

どこ:

- Aは吸収率(単位なし)

- ε(エプシロン)は、摩ル吸収率(物質特有の常数)です。

- b はサンプルを通過する光の経路長さ (通常 1 cm)

- cは物質の浓度です。

正確な量的結果を得るには 素晴らしいパフォーマンスを持つ機械が必要ですこれは,特に吸収率が高いサンプルまたは非常に低い浓度のサンプルに当てはまります.これらの高精度作業では,線性を確保するために,超低ストレーライト (例えば,0.01% T 未満) を持つ儀器が必須です. 「 The PERSEE T10DCS UV-Vis分光計その高度な低迷路光光学、調節可能なスリット幅、およびそのそのそのそのその高高度な低迷路光光光光光光光光光学、そのそのそのその高度な低迷路光光光光学、調節可能なスリット幅、および高度な高度なそのその高高高度の

光分解または光衰効果の監視

時間の経過とともに吸収スペクトルの変化を観察すると,光曝露によって引き起こされる光光光光光光光光光の衰退パターンが見えます.これは生地を推測するのに役立ちます’寿命。

光学ブライトナーおよび仕上げ剤の評価

光学ブライトナーは紫外線を吸収し、青い光として送り出します。その存在は明らかにスペクトルを変える。これにより、少量でさえ見つけることが容易になります。

織物元素分析における原子分光計の役割

有機化合物のほかに、織物は製造中に金属の小さな部分を追加する可能性があります。

技術:原子吸収,放射,原原原子原原原原子吸収,放射,原原原原子吸収法

原子吸収スペクトロスコピー(AAS)と感原原原子吸収スペクトロスコピー(ICP-OES)により、原子吸収スペクトロスコピーは、10億分の1パートレベルまで要素をプロファイルすることができます。

汚染物または

これらの方法は、铅铅铅(Pb)やカドミウム(Cd)などの有害な残留物を見つけるために不可欠です。これにより、製品はREACH(EU)やCPSIA(米国)などの安全規則を遵守することができます。What’子供のために作られた織物のために特に重要です’s 項目。

結論

適切な分析機器を選ぶことは 技術的な詳細を比較するだけではない楽器’長期的な安定性、データの信頼性、将来のニーズに対処する能力は、すべてメーカーから来ます。研究、開発、品質への献身。良いパートナーは,簡単な品質チェックから高レベルの研究まで,あらゆるタスクに堅実な技術的支援を提供できます.

PERSEEについて:技術的強さと品質へのコミットメント

忍耐 分析機器業界で世界的な名前を築きました。これは、技術的改善のための継続的なドライブによって動かされています。同社は将来に多くのお金を投入し、従業員の30%以上が研究開発に従事しています。これにより、その製品は今日だけでなく適合します’s ニーズですが、明日の準備もできます’問題です。この新技術への焦点は、最も厳しい研究のために作られたT10DCSのような高性能システムまで、安定で信頼性の高いエントリーレベルの機器から、その幅広い製品範囲で見ることができます。

さらに,すべてのPERSEE製品は厳格な国際品質基準に従っており,多くのグローバル認証を取得しています.この品質への約束は,迅速に応答するグローバルな顧客サービスチームによってサポートされています.新しいアイデア,品質,サポートへの完全な献身が,PERSEEに多くの国際的な賞を受賞しています.したがって、it has 学校や企業の信頼できるパートナーになる.

よくある質問:

Q1: 単一ビーム分光度計は何を測定しますか?

A: 単一ビーム光谱計は,サンプルが異なる波長でどれだけの光を吸収するかを測定します.光の道を使う。最初に空の溶媒で基準値を読み、その直後にサンプルを測定します。

Q2: 定量的な染料分析のために単一ビームUV-Vis分光度計を使用できますか?

A:はい、確かに。吸収率と浓度を直接結びつけるビール・ランバート法則を使用することで 正確な量的チェックを行うことができますPERSEEのT6Uのような小型機械でも、安定したデュアルランプシステムを備えています。これらは,染料分析における信頼性が高く,繰り返し可能な結果に必要な安定した出力を提供します.

Q3:なぜUV-Visスペクトロスコピーでランプの安定性が重要ですか。

A:ランプの安定性は光’を確認します;明るさは時間とともに同じです。これはベースラインドリフトを減らします。これは測定の精度と繰り返し性に影響を与える巨大な要因です 特に特特特特特特に特特測測測定の精度や繰り返し性に影響を及ぼすとき 特特特に特特に測測測測測測定物の添加物や汚